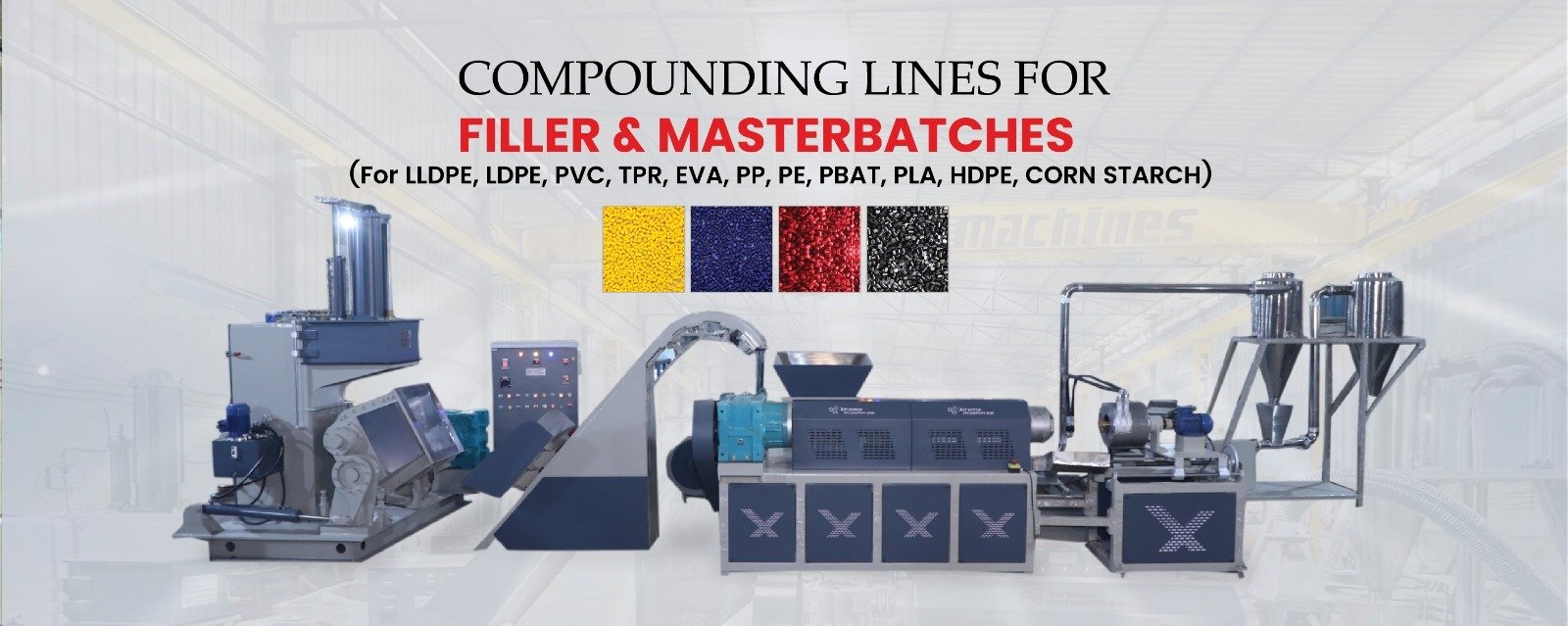

Compounding Lines For Filler & Masterbatches

Xtreme Machines is a maximum first-rate manufacturer and issuer of advanced compounding strains for a big range of industries. Our machines are designed to supply superior average overall performance, performance, and reliability, assisting agencies achieve higher productiveness with minimum downtime. Whether you’re seeking out PVC compounding solutions or specialised machines for bio-based completely polymers, Xtreme Machines has the right era for you.

One of our flagship products is the PVC Compounding Line, designed to meet the challenges of even the most demanding production environments. This line ensures precise mixing and compounding of PVC materials, guaranteeing consistent quality and reliable performance. Perfect for producing a wide range of PVC products such as cables, pipes, and profiles, it incorporates advanced features like automatic temperature control and high-torque mixing for enhanced efficiency. Whether you’re scaling up production or improving operational ease, our compounding line helps streamline the manufacturing process.

Corn starch is becoming a key factor within the manufacturing of bio-primarily based polymers, specially in the introduction of biodegradable plastics. As the demand for sustainable materials grows, Corn Starch Compounding Line Manufacturers have advanced specialised system to technique corn starch effectively.

A kneader-based pelletizing line is an advanced solution designed to deliver high-quality, uniform, and efficient compounding results for a wide range of polymers and filler masterbatches. These systems are particularly suitable for Pelletizing Lines or Compounding Lines for Calcium, Talc, and Sodium-based Filler & Masterbatches used in polymers like PP, PE, LLDPE, PVC, TPR, EVA, and even bio-polymers such as PBAT, PLA, and PBS. They are also ideal for specialized applications like ZHFR (Zero Halogen Flame Retardant) cable compounding. Kneader-based system lies in its intensive mixing and superior dispersion capability, ensuring consistent quality even with high filler loading. Its robust torque transmission, energy-efficient operation, and flexible processing ability make it suitable for both virgin and recycled materials. Unlike traditional twin-screw extruders, a kneader-based pelletizing line offers better thermal control, lower degradation of sensitive polymers, and longer machine life due to reduced wear and tear.

These compounding strains mix corn starch with numerous additives to provide green materials that smash down greater easily inside the environment, imparting a promising opportunity to traditional plastics.

Xtreme Machines also excels in manufacturing Bio Polymer Filler Compounding Machines, which are essential for producing eco-friendly plastic products. Our Bio Polymer Filler Compounding Machine is designed to work with biodegradable materials like PLA, PBAT, and other bio-based resins. The Bio Polymer Filler Compounding Machine integrates the latest technology to ensure precise compounding, offering businesses a competitive edge in the growing biodegradable plastics market. With a Bio Polymer Filler Compounding Machine from Xtreme Machines, manufacturers can achieve high-quality production while adhering to environmental regulations. The Bio Polymer Filler Compounding Machine is perfect for companies that prioritize sustainability and want to deliver green solutions to their customers.

For industries working with EVA materials, Xtreme Machines provides the state-of-the-art EVA Filler Compounding Line. This EVA Filler Compounding Line is tailored for compounding ethylene vinyl acetate (EVA) resins, commonly used in shoe soles, foam products, and adhesives. The EVA Filler Compounding Line from Xtreme Machines offers excellent dispersion and consistency, ensuring that your end products meet the highest quality standards. With advanced control systems and energy-efficient operation, the EVA Filler Compounding Line helps manufacturers optimize their production processes while minimizing waste. The EVA Filler Compounding Line is the perfect choice for businesses seeking reliable and high-performance compounding solutions for EVA materials.

Another cutting-edge solution offered by Xtreme Machines is the TPR Filler Compounding Line, which is designed for processing thermoplastic rubber (TPR) materials. The TPR Filler Compounding Line ensures optimal mixing and dispersion of fillers and additives, producing high-quality TPR compounds for various applications. The TPR Filler Compounding Line is ideal for the footwear industry, automotive parts, and flexible tubing manufacturing. With the TPR Filler Compounding Line, manufacturers can achieve superior flexibility, durability, and performance in their final products. Xtreme Machines’ TPR Filler Compounding Line is engineered for efficiency and ease of use, making it a preferred choice for businesses looking to enhance their production capabilities.

In addition to TPR, Xtreme Machines offers the advanced PE Filler Compounding Line, which is specifically designed for polyethylene (PE) materials. The PE Filler Compounding Line ensures precise mixing and compounding, delivering consistent quality for applications in packaging, construction, and consumer goods. The PE Filler Compounding Line is known for its energy efficiency and ability to handle large production volumes, making it ideal for businesses with high demands. With the PE Filler Compounding Line, manufacturers can achieve excellent product quality while reducing operational costs. The PE Filler Compounding Line is a top choice for companies seeking reliable and efficient compounding solutions.

Xtreme Machines also specializes in ZHFR Cable Filler Machines, which are designed for zero halogen flame retardant (ZHFR) cable applications. The ZHFR Cable Filler Machine ensures that the compounding process meets the stringent safety and environmental regulations required for flame retardant cables. The ZHFR Cable Filler Machine offers precise control over the compounding process, resulting in superior flame resistance and durability. With the ZHFR Cable Filler Machine, manufacturers can produce high-quality ZHFR cables that are both safe and environmentally friendly. The ZHFR Cable Filler Machine is an essential tool for businesses in the cable manufacturing industry.

Applications:-

- Bio Polymer

- Non Wooven Bags

- Carry Bags

- Wooven Sack Bags

- Garbage Bags

- Tarpals

- Engineering Plastics

- PVC Cable compounding

- PVC Footwear & Soles

- Pipe Industries

- Tank Industries

- Injection Moulding

Capacities Available: 25KG/HR,50KG/HR, 100KG/HR,150KG/HR,200KG/HR, 350KG/HR,700KG/HR 1200KG/HR. We also provide Die Face Cutter separately in Air & Water on demand

ASSURED QUALITY

Quality has always remained the integral part of our endeavors. To provide our clients with a superlative range of Rubber and Plastic Processing Machinery, each and every manufacturing processes is supervised by an expert team of quality controllers who keep a close vigil on the life cycle of the machines, starting from procurment of raw material till the final dispatch.

INFRASTRUCTURE & TEAM

Our 2000 Sq.Yards infrastructure consists of an in-house manufacturing unit outfitted with cutting-edge technology and the most advanced machinery, upgraded as per the latest techology. Our team of quality professionals possess years of experience and expertise, which has helped us be the best in the industry. We also have with us a diligent R & D team engaged in carrying out regular market research and analysis.

NETWORK

We have got a vast network of distributors to our credit. Our Rubber and Plastic Processing Machinery cover the entire global markets of : Spain, Dubai, Saudi Arabia, Venezuela, Iraq, Jordan, South Africa, Kenya, Nigeria, Nepal and Bangladesh.