Dispersion Kneader Pneumatic/Hydraulic

In the world of rubber production, the Dispersion kneader stands as a cornerstone in the manufacturing system. This specialised system performs a pivotal position in mixing, blending, and dispersing various elements within rubber compounds. Whether inside the introduction of tire materials, rubber merchandise, or industrial parts, a dispersion kneader ensures that the components are uniformly allotted, providing super, durable, and consistent rubber output.

A Dispersion kneader is prepared with a pair of counter-rotating rotors, which paintings collectively to mix the rubber and its components. The rotors are designed to create excessive shear forces that wreck down aggregates and lightly distribute fillers like carbon black, oils, and other additives. The end result is a homogeneous mixture, that’s important for achieving most reliable overall performance in completed rubber merchandise. The green operation of the kneader guarantees that the rubber well-knownshows the preferred electricity, flexibility, and durability.

The time period Rubber kneader refers to any kneading gadget used particularly inside the rubber industry for the purpose of preparing rubber compounds. These machines are designed to fulfill the stressful requirements of rubber manufacturing, where precision and consistency are of utmost significance. The kneader works by subjecting the rubber materials to continuous mechanical forces that help in breaking down clumps and making sure a easy consistency.

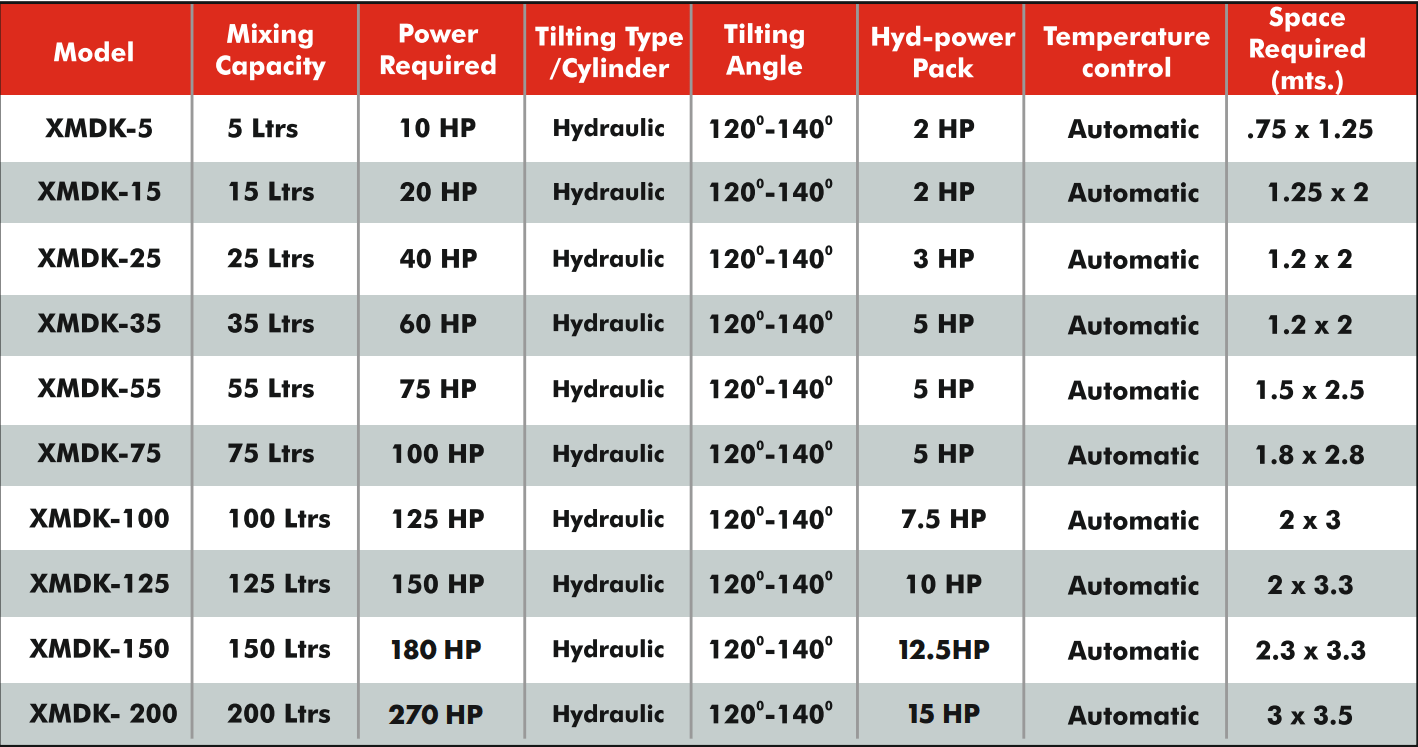

Modern Rubber kneader machines feature advanced technologies that enhance their performance, reduce energy consumption, and increase output. These innovations also assist in minimizing the damage and tear of the gadget additives, thereby extending the lifespan of the equipment. The design of the rubber kneader consists of quite a few features together with temperature control, adjustable rotor velocity, and variable load capacities, making it adaptable to one of a kind production needs.

A Kneader machine is a flexible piece of gadget used in numerous industries beyond simply rubber manufacturing. This machine is capable of processing a extensive variety of substances, from plastics to food merchandise, or even prescribed drugs. Its key position lies in its capacity to combine, knead, and blend elements to create a uniform product. In rubber production, the kneader machine is vital for reaching the proper balance of viscosity, consistency, and uniformity in the very last product.

The Kneader machine is frequently designed with features that make sure the green transfer of warmth, making it less difficult to control the processing temperature. This is particularly critical in rubber manufacturing, where temperature control affects the houses of the compound. Furthermore, the kneader gadget can be customized to address precise manufacturing volumes, making sure that manufacturers can scale their operations with out compromising on best.

Whether you’re managing a dispersion kneader, rubber kneader, or kneader system, those portions of system are critical to the a hit manufacturing of high-quality rubber compounds. Their ability to combination substances successfully, manipulate temperature, and provide steady consequences makes them an essential part of the manufacturing manner. For groups in the rubber enterprise, investing in a dependable kneader device ensures superior product excellent, elevated production efficiency, and a aggressive side inside the marketplace.

Each kind of kneader system is designed to meet precise needs, however all percentage the commonplace goal of creating high-performance rubber compounds that are long lasting, bendy, and precisely engineered for their meant packages.

Applications:-

Plastic Industries

- PP/E.V.A/P.V.C/T.P.R/Foam & Sandal

- P.V.C. Artifical Leather

- P.V.C Floor Tile

- P.V.C. Sheet

- Automobile P.V.C. Accessories

- P.E. for cable industries

- HIPS/ABS

- Compunding & Masterbatches

- P.V.C./E.V.A. Toy

- L.D.P.E./L.L.D.P.E./H.D.P.E.

- Battery & Plastic Blends

- Reclaim Plastic

- Pencil Industry

Rubber Industries

- Rubber Sole, Heal & Pad for shoes

- Rubber Sponge & Rubber Sandal

- Tyre & Tube for bycycle, Motorcycle & Automobile

- Rain Boot, Rain Coat & Rubber Boot

- Automobile Rubber Accessories

- Marine Fenders

- V Belt & Conveyor Belt

- Sports Ball & Balloons

- Printer Roller & Rice Roller

- O Ring and Oil Seal

- Milk Nipple & Rubber Toys

- Reclaim Rubber, etc.